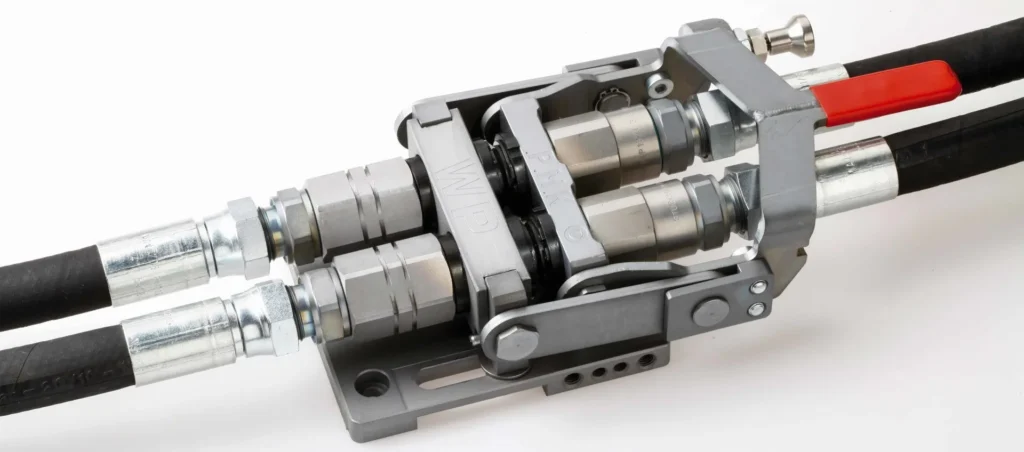

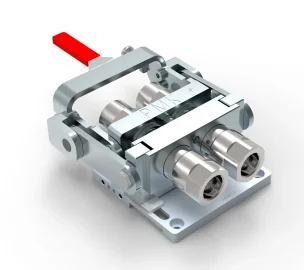

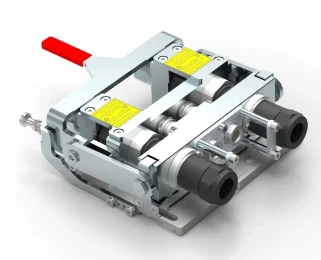

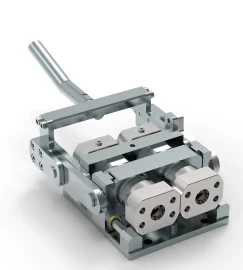

Pister quick coupling system PMK

The Pister quick coupling system PMK is a mechanical quick coupling system to connect and disconnect hydraulic lines between construction machinery and attachments

The system was especially designed for use at construction machinery . It can be used for quick tool exchange but also for boom separation at large demolition excavators

With the system up to four hydraulic circuits can be coupled simultaneously to connect any tool to the construction machine in no time. Without leakage and under any residual pressure in the attachment.

The system can be used with hammers and all kind of demolition tools without any limits. Available from

nominal size ten to 25.

Fast tool exchange will increase the efficiency of the machine, reduces idle mode for tool exchange, and wearout costs due to more regular tool exchanges

Features:

• Self locking in coupled position

• From nominal size DN20 and above with locking device to avoid opening when line is pressurized

• Machine side : plugs tool side : female couplings

• Couplings with different nominal sizes in one multicoupling

possible

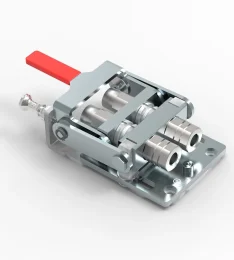

• Individual configuration of tool plates according to attachment requirements . Dummies to protect empty lines

• Knee lever mechanism for optimal force deflexion characteristics

• Anti twist safeguard to increase the lifespan of couplings

• Robust by use of hardened steel

• Zinc nickel coating

Benefits

+ Additional runtime for construction machinery increase efficiency

+ Lower maintenance costs due to lesser replacement parts and

therefore additional time savings due to lesser repairs

+ No oil leakage and possibilty to work in sensitive areas such as

gardening and landscape works

+ Low additional weight on the boom increase machine

performance and saves fuel compared to fully automated systems

+ No danger of confusion between hydraulic lines

+ Installation sideways on the boom reduces dirt impact

+ Unlimited use of any demolition tools and hydraulic hammers

+ Extremely flat and compact design reduces the risk of damage

+ Easy and fast installation especially with adapter plates

+ Only two sizes for machines up to 45 tons . maximum

compatibility

+ Existing tools can be easily adapted at a fair price

+ Screw adapters allow use of rental tools

PMK-10 series

available as a single or double system

Tonnage class: 1-3t

Flow rate: 50-75l/min. at 3/5bar pressure loss

Operating pressure: 330 bar

Coupling type: 1

PMK-13 series

available as a single, double or triple system

Tonnage class: 2-9t

Volume flow: 90-125l/min. at 3/5bar pressure loss

Operating pressure: 330 bar

Coupling type: 1

PMK-20 series

available as a single, double or triple system

Tonnage class: 10-40t

Volume flow: 280-380l/min. at 3/5bar pressure loss

Operating pressure: 450 bar

Coupling type: 2

Wheel loaders and special machines

available as a double system

Tonnage class: up to 25t

Volume flow: 170-200 l / min. at 3 / 5bar pressure loss

Operating pressure: 330 bar

Coupling type: 1

Material handling machines

available as a quadruble system

PMK-25 series

available as a double system

Tonnage class: from 30t

Flow rate: 650-800/min. at 3/5bar pressure loss

Operating pressure: 375 bar

Coupling type: 2