HRC Railcutter

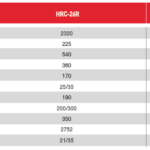

Hydraram HRC railcutter has been designed to cut rails in metal recycling process. Cutter is very strong and there are three different models. HRC-26R is typically the most optimal cutter around the world. There are still some bigger rails those will require HRC-42R. Cutter can process quite easily 15-20 cuts per minute once material is set up nicely for the cutter.

Strong rotation easy out the operation and operator can pick up rails from the pile.

The effectiveness is combination of power and design of the cutter. Rail material doesn´t need sharpness of blades as much as typical shears. Big jaw axle is important part of design to keep cutting process stable. HRC-26R can be used by +20tn machine. HRC-42R will require +30tn excavator.

Hydraram railcutters are used commonly worldwide. Reliability has been always great benefit for these cutters.

Benefits

+ Made by HARDOX-400® steel

+ Strong and reliable

+ Blade design

+ Fast cutting cycle