SQUALO 2000 INCLINE SHEAR

Cost effective and very simple incline shear for professional scrap metal recyclers.

The Bonfiglioli line of “Squalo” vertical guillotine shears are the most powerful shear

available in the market. It is the best choice available for processing all kinds of HMS

such as beams, rails, pipe, re-rod, skeleton plate, tanks and other types of heavy

material.

The vertical cut shear model Squalo 2000 is constructed of special steel Hardox 500.

It can be equipped with either diesel engine or electric power according to the

customer preference. It is a mobile and versatile solution able to size metal scrap into

marketable length on site. The unit is fully automatic and controlled primarily by PLC

system.

Thanks to the integrated hydraulic jib it can take material inputs up to approximately

18m in length. This will greatly reduce the need for oxy cutting and “nibbler” type

shearing in scrap processing operation that are required to size or prep material for

shipment or further processing.

The Squalo 2000 shear is equipped with 4 lifting cylinders that allow it to easily lift

itself onto a goose neck or low-boy trailer.

The shear is equipped with 4 lifting cylinders to move it easily on goose neck or low

boy trailers. The shear blades have 4 cutting edges. Each cutting edge lasts approx.

250/300 hrs (depending on the type of processed material). The same set of shear

blades can be used for additional +/- 1000 working hours after being reconditioned

using a set of shims.

The machine also is equipped with an automatic lubricating system is lubed by a

central grease pump.

The unit will powered by a diesel engine or electric motor or combo motorization

(diesel engine and electric motor), according to the customer’s need.

The crane operator feeds the machine from the top of the charging hopper, the

oscillating “walking floor” built into the jib assists in moving the scrap to the shear

head. Two lateral compacting rams and a vertical blank holder compress and position

the material to be cut vertically by guillotine shear action of the shear blades powered

by the main hydraulic cutting rams.

Check out technical details and contact us.

Advantages:

+ Movable and easy to install

+ Diesel or electric

+ Low fuel consumption

+ Easy feeding for long materials

+ Low operational cost

+ Effectiveness

+ Simple and strong structure

+ Can process different materials

+ Cutting force 1200tn!

Technical details:

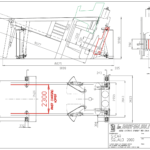

Structure:

Length: 8630 mm

Width: 2550 mm

Height: 3260 mm

Weight: 69 tn

Features:

Cutting cycle : 30 s

Remote control: Kyllä

Capacity: 18-20 tn/h

Champer width: 2300 mm

Cutting force: 1200 tn

Cutting:

Min. cutting size: 450 mm

Adjustable cutting : 450 / 640 / 830 / 1020 mm

Max. cutting size: 283 mm (pyöreä) / 250 mm (neliö)

Fuel consumption: approx. 16 l/h

Motor:

Diesel: CAT C7 270HP / Cumming QSB 6,7 220HP

Electric: Electro Adda 160kW

Hydraulics:

Hydraulic oil tank: 1600 l

Hydraulics: Sauer Danfoss, Bosh rexroth, Danison Parker

Service:

Daily greasing

Basic service program for engine

Oil filling

Spare- & wearparts:

Turnable cutting blades. 4 cutting edges per blade. Turn approx. every 300h.

Blade last approx. 4 x 300h = 1200h

Possible to use longer with filling part.

Bolts recommended to change every 2000h