OPTICAL BELTSCALE

Would you like to follow the productivity and collect the data of your machine?

Deeper information you can read from official OPTICAL-BELTSCALE home page from this link.

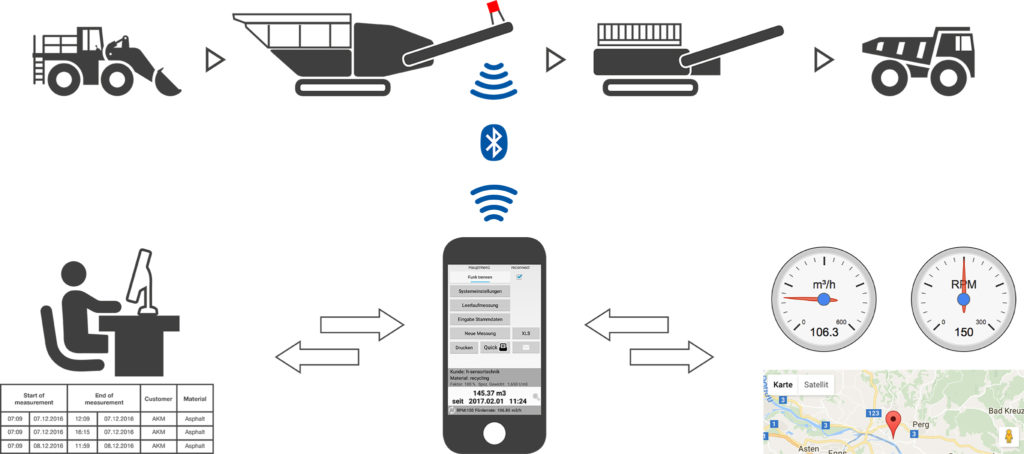

The electronic measuring system for bulk material measures the volume on the discharge belt via an electronic-optical sensor and transmits data directly to your smartphone. From there, the recorded information is being sent to the selected computers.

Optimally coordinated sensors recognize any detail of the material quality being conveyed. High-quality technical components guarantee error-free, flexible transmission possibilities and simultaneously enable a complete monitoring of complex production capacities.

No matter what material, after a single calibration, nothing remains hidden from the highly sensitive sensors. Every detail is collected and analyzed electronically. In addition to the usual materials, the task areas are constantly expanded. Infos by telephone or e-mail.

The optical beltscale has been developed by the Austrian H-Sensortechnik to measure cubic meters from belt conveyor. Especially standard solution fits perfectly for mobile shredders/grinders and wood chippers.

The compact, easy-to-use, durable and reliable volume scale will now revolutionize the market!

The optical scale measures the material from the belt conveyor. This information will be followed in real time via a Bluetooth connection on a mobile device. The data is also stored in the measuring device and is available afterwards. The results can be printer to the receipt at jobsite for the end client if needed.

The device is suitable for heavy use and works in cold weather, as well as in hot weather. The measuring device is suitable for any type of belt conveyor. The data can be connected for any type of software interface if measuring is needed in stationary lines that has existing control system.

Operating system has different language options!

How does it work?

1. The device measures the surface area of the material bed to be conveyed and compares the data with the speed of the belt that measured by an inductive sensor from pulley. The data will be collected to the measuring unit and results will be tranferred and followed from mobile device by bluetoot connection.

2. In the program can be create different customer- and material profiles. The data can be printed out or sent by email forward.

With this revolutionary measuring device bioenergy operators have opportunity to prove the cubics that made for pthe clients faster and easier than ever before.

Advantages

+Resistant to temperature, wind, dust, and vibrations

+Regardless of belt angle and its change

+ Only a single calibration

+No moving parts, no contact with the material and therefore no wear

More information needed? Please contact:

Kalle

+358408342178

kalle(at)minimumagent.com